production of alumina from bauxite ore

2022-03-15T18:03:56+00:00

Alumina Production an overview ScienceDirect Topics

The RM as the bulky waste of the Bayer alumina production process, is formed as the result of the reaction between sodium hydroxide and bauxite ore The bauxite ore is usually a combination of minerals rich in aluminum oxide and hydroxide However, bauxite also contains minerals of iron, silicon, titanium and rare earth elements For each ton of alumina produced, Chapter 2 Production and Processing of Aluminum the 19th century, is by far the most important process used in the production of aluminum oxide from bauxite The process has been refined and improved since its inception Fig 22 shows that the production of alumina is a complex chemical process The alumina content of bauxite ores varies from one deposit to another, process for the production of alumina from bauxite ore06102021 The Bayer Process, which is used by about 80 active plants worldwide, is the primary method of producing aluminum from bauxite Bauxite ore is dissolved in sodium hydroxide, or lye, at a high temperature and pressure Then, the alumina and bauxite ores are separated by washing out the waste (red muds or sands) from the aluminaTENORM: Bauxite and Alumina Production Wastes US EPA

How to Get Aluminum from Bauxite Reduction Process

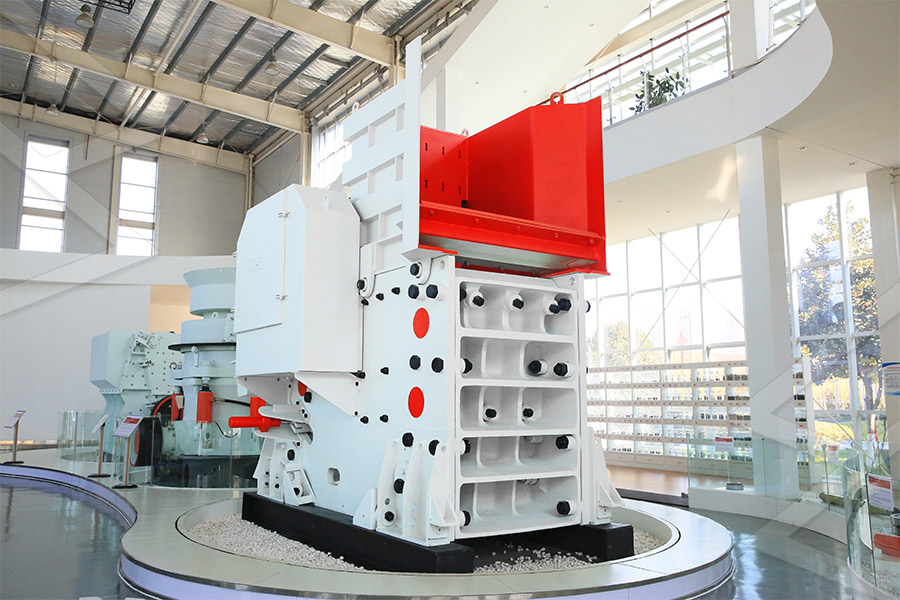

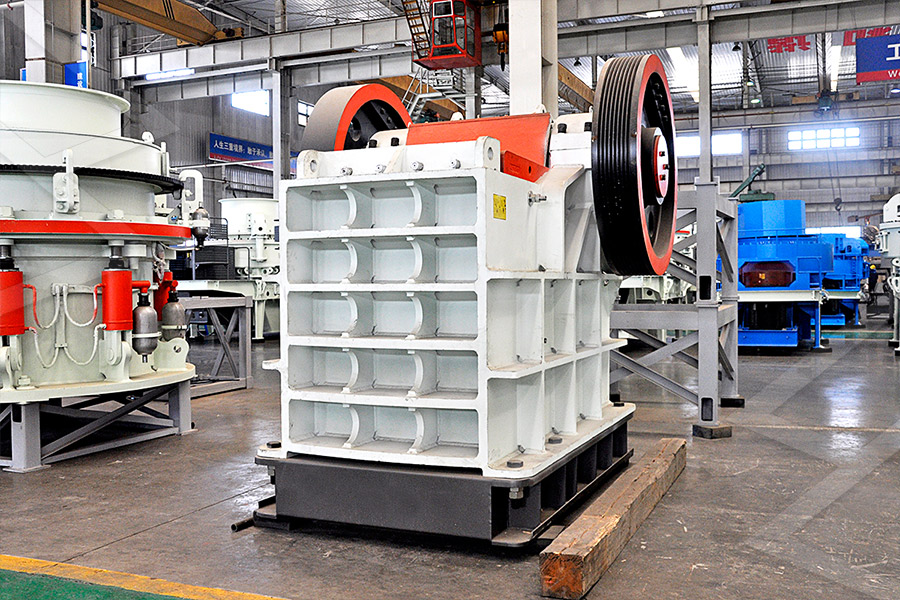

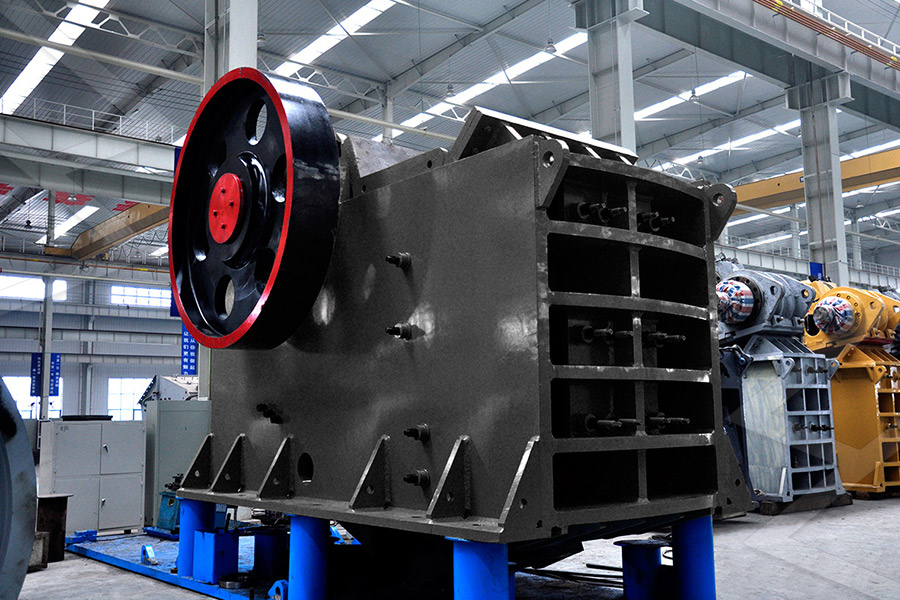

28102021 Bayer process steps for alumina production As the bauxite is found near the surface, it needs an openpit mining Step 1 Crushing process The first step of the Bayer process is to use the crushing equipment to crush This method of obtaining alumina from bauxite ore is complex and involves a lengthy succession of chemical reactions, with the process varying slightly depending on the makeup of the unique source of bauxite ore Crushed and The Transformation of Bauxite to Aluminum (and the 08052014 Alumina refining produces alumina (Al 2 O 3) from the bauxite ore, by exploiting the reversible reaction of the Bayer process 1–3 : The reaction is firstly driven in the sodium aluminate (NaAlO 2) direction by the addition of caustic soda (NaOH) to bauxite Bauxite residues are then removed, leaving the process liquid, termed “green liquor”Bauxite Mining and Alumina Refining PMC

Bauxite and Alumina Statistics and Information US Geological

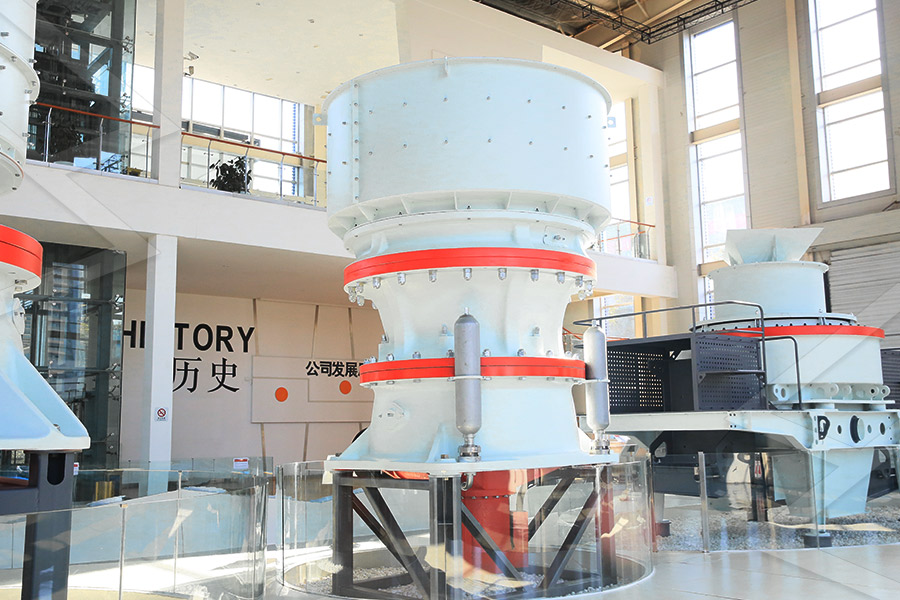

Bauxites are typically classified according to their intended commercial application: abrasive, cement, chemical, metallurgical, refractory, etc The bulk of world bauxite production (approximately 85%) is used as feed for the manufacture of alumina via a wet chemical caustic leach method commonly known as the Bayer processThe Bayer process is the principal way for producing alumina by refining Bauxite Bauxite other than with 3060percentage of aluminium oxide contains mixture of silica, iron oxides and titanium dioxide Bayer process of producing Bayer Process: Manufacturing Of Alumina Making of Two to three tonnes of bauxite are required to produce one tonne of alumina 90% of the global alumina supply of around 90 million tonnes is used in aluminium production Alumina refineries tend to be located close to bauxite Mining and Refining – Process World Aluminium

process for the production of alumina from bauxite ore

Chapter 2 Production and Processing of Aluminum the 19th century, is by far the most important process used in the production of aluminum oxide from bauxite The process has been refined and improved since its inception Fig 22 shows that the production of alumina is a complex chemical process The alumina content of bauxite ores varies from one deposit to another, The bulk of world bauxite production (approximately 85%) is used as feed for the manufacture of alumina via a wet chemical caustic leach method commonly known as the Bayer process Subsequently, the majority of the resulting alumina produced from this refining process is in turn employed as the feedstock for the production of aluminum metal by the electrolytic reduction Bauxite and Alumina Statistics and Information US Geological The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef BayerBauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al 2 O 3), the rest being a mixture of silica, various iron oxides, and titanium dioxide The aluminium oxide must be purified before it can Bayer process Wikipedia

Bauxite an overview ScienceDirect Topics

122 ALUMINA FROM BAUXITE: THE BAYER PROCESS Bauxite, the principal ore used for aluminum smelting, is named after Les Baux, Provence, the village where the first deposits were discovered Bauxite contains hydrated alumina equivalent to as much as 40–60% Al 2 O 3, and is free of the other siliceous materials leached out over time However it Bauxite ore is the world’s main source of aluminum Bauxite is a rock formed from a reddish clay material called laterite soil and is most commonly found in tropical or subtropical regions Bauxite is primarily comprised of aluminum oxide compounds (alumina), silica, iron oxides and titanium dioxide Approximately 70 percent of the world’s Bauxite 101 The Aluminum Association12012022 Bauxite is composed of aluminium oxide compounds (alumina), silica, iron oxides and titanium dioxide Aluminium is obtained by the Electrolysis of Alumina The concentration of the Bauxite ore into alumina is done by Bayer’s process Alumina is then refined into pure aluminium metal through the Hall–Héroult electrolytic processExtraction of Aluminium from Bauxite by Bayer's Hall's Process

production of alumina from bauxite ore

Mar 10 2015 Aluminum production and the bauxite and alumina that make up the with the aim of improving transport for potential iron ore and bauxite Chapter 2 Production and Processing of Aluminum Production and Processing of Aluminum Fig 2 2 shows that the production of alumina is a complex other than the type of bauxite ore to be used as feed Bauxite Cim 08082021 Alumina is extracted from the ore bauxite by means of the Bayer process at an alumina refinery This is an electrolytic process, so an aluminium smelter uses huge amounts of electricity; smelters tend to be located close to large power stations, often hydroelectric ones, in order to reduce the overall carbon footprintAluminium Industry In India UPSC05082021 In the leaching of alumina from bauxite, the ore expected to leach out in the process by reacting with NaOH is : ← Prev Question Next Question → +2 votes 23k views asked Aug 5, 2021 in Chemistry by Harshal01 (440k points) In the leaching of alumina from bauxite, the ore expected to leach out in the process by reacting with NaOH is : (1) TiO 2 (2) In the leaching of alumina from bauxite, the ore expected to

Bauxite Distribution In India UPSC Lotus Arise

13052021 The plants for obtaining alumina from bauxite ore, Orissa is the largest producer, which produces about 50% of the total bauxite production of the country The main bauxite belt is in Kalahandi, Koraput, and Baragarh districts This is the largest bauxitebearing region of the country This 300 km long, 40 to 100 km wide and 950 to 1300 metre thick belt is 06102021 Bauxite is used to produce alumina, which is then used to produce aluminum Wastes can be generated at several points in the production process, including during the mining of the bauxite ore, and during the refinery production process The refinery processes used to produce aluminum generates about 2 – 25 tons of solid waste for every 1 ton TENORM: Bauxite and Alumina Production Wastes US EPAAlumina is produced from bauxite, an ore that is mined from topsoil in various tropical and subtropical regions The Bayer process, discovered in 1887, is the primary process by which alumina is extracted from bauxite entrepreneurindiaco Bauxite is the general name given to the hydrated oxides of aluminium It contains varying amounts of combined water and Alumina from Bauxite Extraction and Production of Alumina from Bauxite

Bauxite Mining and Alumina Refining PMC

08052014 The bauxite ore, Bayer process materials before precipitation, mud residue, and sand residue are therefore of radiological interest, whereas the alumina product is not8 Positional and personal monitoring data from bauxite mines and alumina refineries in Western Australia have been used to assess the abovebackground annual doses for the workforce Bayer process of producing alumina can be divided into following four steps: i Digestion: In this step of Bayer process, bauxite ore is crushed, milled and then heated with sodium hydroxide at the temperature of around 150200 degree Celsius In the Bauxites, aluminium compounds are present as gibbsite (Al (OH) 3), boehmite (AlOOH) and Bayer Process: Manufacturing Of Alumina Making of AluminaThe bauxite ore, Bayer process materials before precipitation, mud residue, and sand residue are therefore of radiological interest, whereas the alumina product is not 8 Positional and personal monitoring data from bauxite mines and alumina refineries in Western Australia have been used to assess the abovebackground annual doses for the workforce across a range of Bauxite Mining and Alumina Refining: Process Description and

Extraction of Aluminium from Bauxite by Bayer's Hall's Process

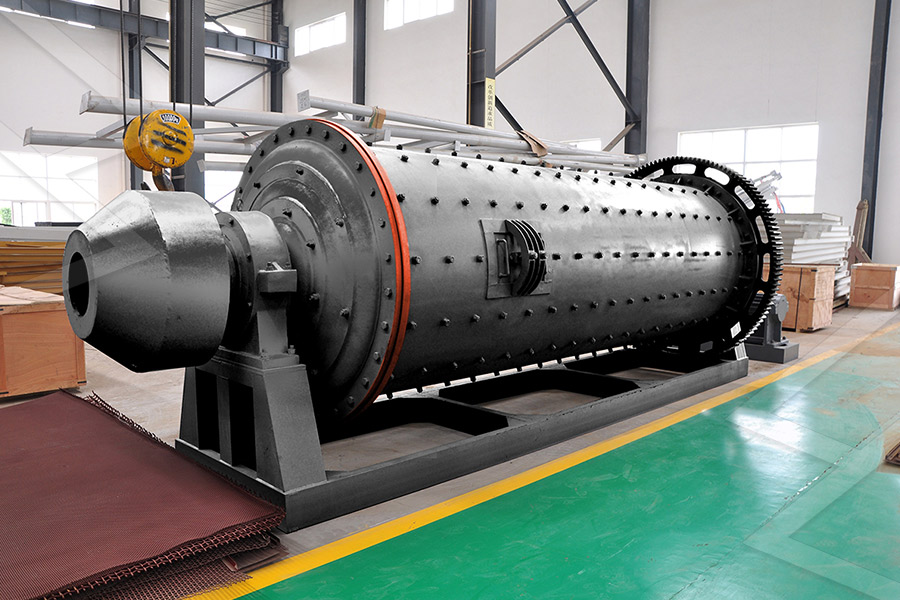

12012022 Bauxite is composed of aluminium oxide compounds (alumina), silica, iron oxides and titanium dioxide Aluminium is obtained by the Electrolysis of Alumina The concentration of the Bauxite ore into alumina is done by Bayer’s process Alumina is then refined into pure aluminium metal through the Hall–Héroult electrolytic processThe production of the metal Aluminum from the raw ore of Bauxite is a two stage process Stage 1 Converting Bauxite to Alumina STEP 1 Crushing and Grinding: Alumina recovery begins by passing the bauxite through screens to sort it by size It is then crushed to produce relatively uniformly sized material This materials is fed into a large grinding mill where it is How Aluminum is Produced Mineralnepheline ore yields 1 tonne of alumina, 9–11 tonnes of cement, 06–08 tonnes of soda ash, and 02–03 tonnes of potash According to the grade of the bauxite ore, 2–3 tonnes of ore yield one tonne of alumina and about one tonne of red mud Chapter 2 Production and Processing of Aluminum TMS

production of alumina from bauxite ore grinding roll

List of countries by bauxite production Wikipedia Bauxite is the most important aluminum oreThis form of rock consists mostly of the minerals gibbsite Al(OH) 3, boehmite γAlO(OH), and diaspore αAlO(OH), in a mixture that usually includes the two iron oxides goethite and hematite, and may include the clay mineral kaolinite, and small amounts of the titanium Bayer process is the process of refining alumina from bauxite (aluminum ore containing 3050% of hydrated aluminum oxide) by selective extraction of pure aluminum oxide dissolved in sodium hydroxide Prior to the Bayer process bauxite is crushed and ground in mills to fine particles (max size 006”/15mm) A hot solution of the recycled sodium hydroxide (caustic BAYER PROCESS idconline