gravity seperation of iron

2021-07-20T05:07:08+00:00

Gravity separation of Iron ore Iron separation by YouTube

05072018 Separation of Iron concentrate from Grind Iron Ore by the process of gravitational separation The gravity separator is used for the separation of iron and silica from iron ore by the principle of08092020 Gravity separation process and strong magnetic separation process are mainly used to separate coarsegrained (2mm20mm) and mediumgrained weakly magnetic iron ore Among them, coarse and extremely coarse (greater than 20mm) ores are commonly used in heavy medium or jigging gravity separation technology ;Separation process of iron ore,iron ore magnetic Gravity Seperation Technique Of Iron Ore Oct 12 2018nbspGravity separation is a physical process which consists of the separation of different mineral types in the ore from one another based on differences in their specific gravities using the force of gravity which can be influenced by one or more of other forces such as centrifugal force resistance to motion by a Gravity Seperation Technique Of Iron Ore appsundreamde

gravity seperation of iron

gravity seperation from iron ore Solution for ore mining gravity separation of iron ore – Stone Crusher MachineGrinding The appliion of gravity concentration Suitable for reelection with large density difference between the ore or other raw materials processing of useful minerals Read more Pyrite gravity separation effect process and equipment Pyrite gravity separation 7488 gravity separation iron ore centrifuge scribdIntroduction gravity concentration process is the oldest beneficiation method known to mankind this is a physical process and exploits the differences in densities of minerals to bring about a separation although with the advent of froth flotation, the relative importance of gravity concentration A Beneficiation Study Gravity Separation Of Iron Ore ccebambergdeIn cases in which the processes of sedimentation and gravity separation are insufficient to cause the settlement of suspended solids, certain chemicals (such as alum, starch, iron materials, activated silica, and aluminum salts) are added to cause settlement of the solids This process is then called coagulation The process of coagulation is highly dependent on the temperature Gravity Separation an overview ScienceDirect Topics

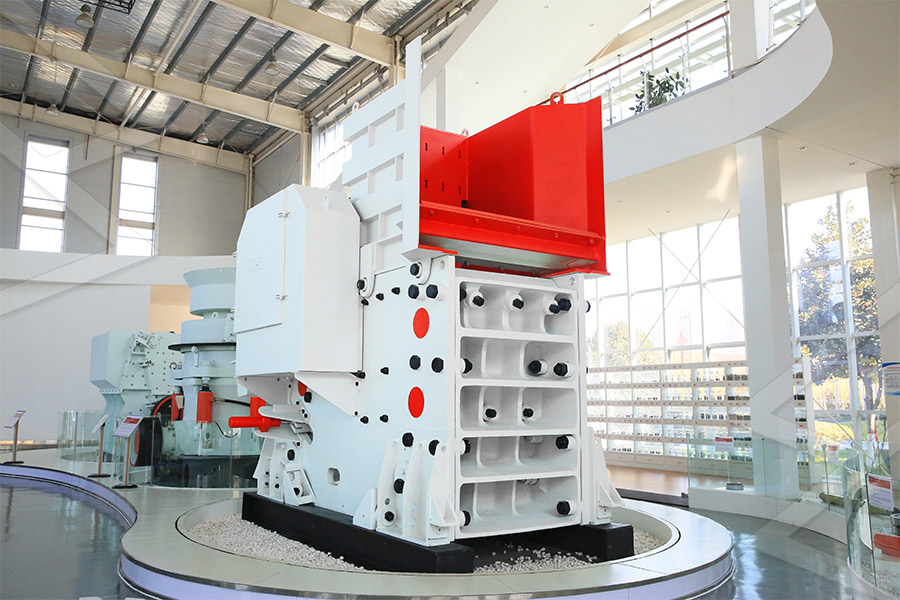

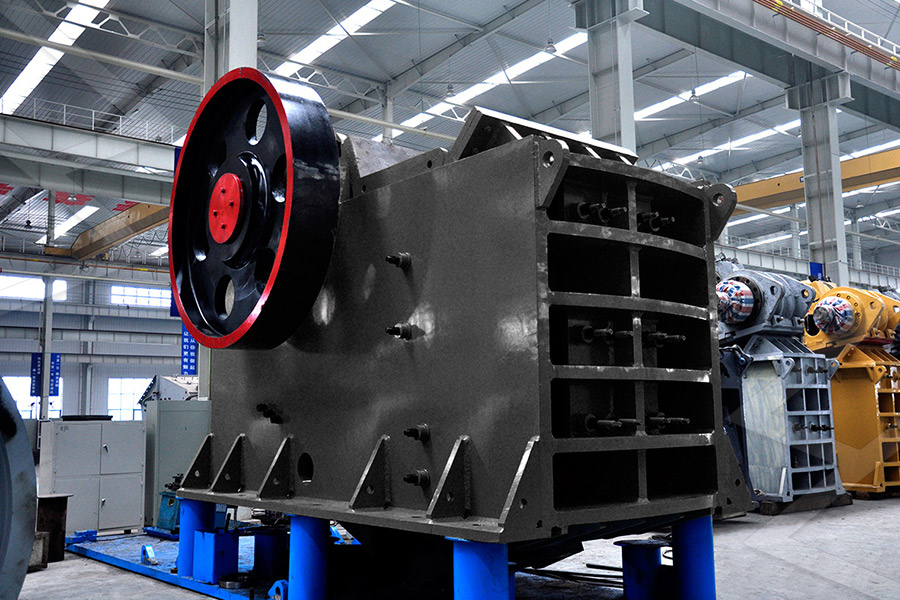

Iron Ore Jigging Separation Processing Plant

Only iron granules are liberated from other impurities, the jig gravity separation can help to get qualified iron concentrate Of course, the premise is that there is density difference between iron granules and its gangues The following picture is about the specularite iron upgrading in Hainan, China Tailings Specularite Iron Concentratein this research work It is clear that the iron content is relatively low, in the range of Effective processing of lowgrade iron ore through separation techniques 571 36% Fe, and the major (PDF) Effective processing of lowgrade iron ore through Gravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical: ie the components of the mixture have different specific weight All of the gravitational methods are common in the sense that they all use gravity as the dominant forceGravity separation Wikipedia

Separation of ultrafine particles using the REFLUX Graviton

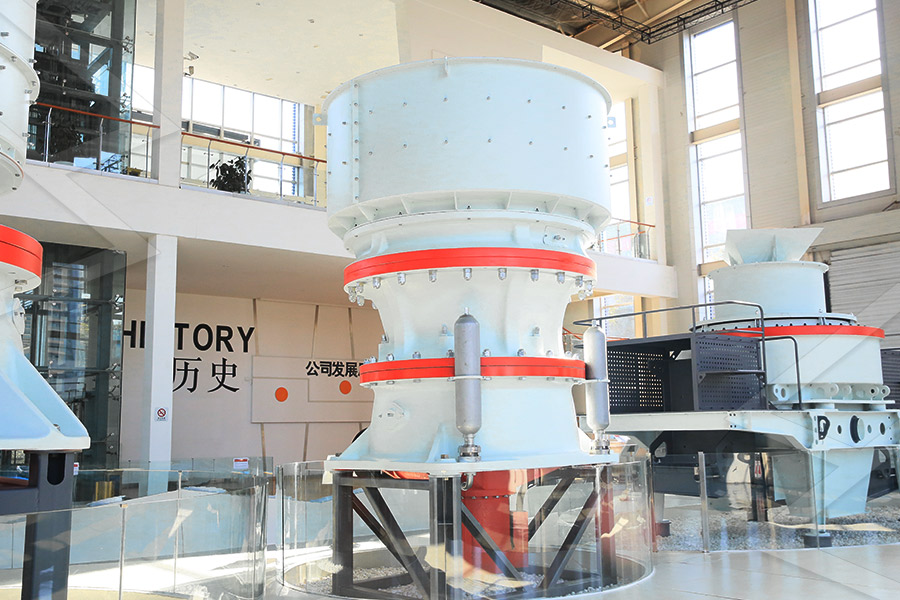

Wet beneficiation of iron ore fines less than 1 mm typically involves a desliming stage ahead of the fine gravity separation such as spirals The desliming is achieved using a bank of cyclones The reject ultrafines emerge in the overflow stream at relatively low pulp density, contain high proportions of lowvalue slimes, but also wellliberated iron ore ultrafines below 0045 mm in Magnetic Gravity Separation Of Iron Ore NISCAIR Usachyov amp korytny magneticgravity separation of iron ore table lcomposition of magnetite concentrates of the kostomuksha combinat size class, mk output, content, degree of magnetite fe si summary magnetite liberation, magnet nonore aggregates ii stage separation concentrate Read Moregravity separation process of iron ore17122020 Gravity separation and magnetic separation are mainly used to separate coarsegrained and mediumgrained weakly magnetic iron ore 20~2 mm During gravity separation heavy medium or jigging methods are commonly used for the gravity separation of coarse and very coarse 20 mm ores; spiral chutes shakers and centrifugal gravity seperation of iron

Magneticgravity separation of iron ore NOPR: Home

Magneticgravity separation of iron ore P A Usachyov S Yu Korytny Mining Institute, Kola Science Centre, Russian Academy of Sciences, 24 Fersman str, Apatity, Munnansk region, Russia Received 17 October 1997; accepted 30 April 199'S In order to produce highgrade ironore concentrates a magneticgravity method has been developedgravity separation and ore beneficiation ispatguru Oct 12, 2018 Separation of the ore particle by gravity is dependent on two factors namely (i) settling rate of the particles, and (ii) difference in specific gravity when compared against the medium in which they are being separated, this gives differential settling rate and has been termed the ‘concentration criteria’Settling rate of gravity separation ironGravity Separation Spirals are the most practical equipment to use for gravity separation of iron ores because of the high throughputs needed SGS has a variety of spiral test rigs including the spiral designs typically used in ironore plants Our accessory equipment allows sizing of feeds multiple spiral stages and recycling of products Extraction and separation of manganese and gravity separation of iron ores production

gravity seperation of iron

31082020 Magneticgravity separation of iron ore NISCAIR Magneticgravity separation of iron ore P A Usachyov S Yu Korytny Mining Institute, Kola Science Centre, Russian Academy of Sciences, 24 Fersman str, Apatity, Munnansk region, Russia Received 17 October 1997; accepted 30 April 199'S In order to produce highgrade ironore concentrates a magnetic The main mechanicalphysical methods for PCB recovery include magnetic separation [15,16], gravity separation [17,18], electrostatic separation [19,20], and vacuum metallurgy [21,22]The highgradient magnetic separator has been applied to the separation of paramagnetic iron elements from metal concentrates [23,24], which could obtain the magnetic (MA) and non Gravity Seperation Of IronGravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical: ie the components of the mixture have different specific weight All of the gravitational methods are common in the sense that they all use gravity as the dominant forceGravity separation Wikipedia

gravity separation iron

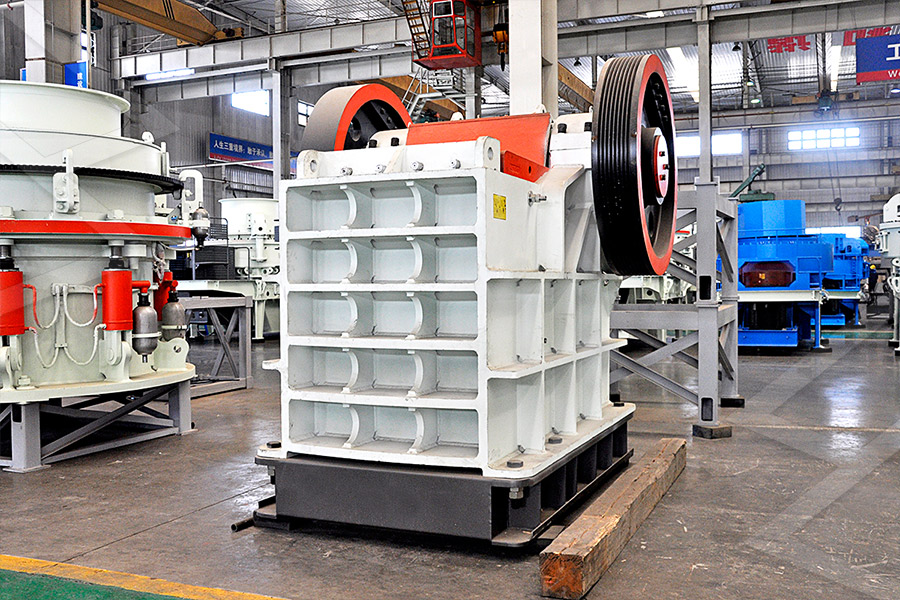

Gravity Separation Method Using Iron Powder 1 a gravity separation method using iron powder comprising mixing and suspending said iron powder composed of fine particles having a size of 40 microns or less in water to form a liquid having specific gravity within the range of 26 to 35, depending upon the intended use, and pouring various raw materials such as metals or 12102018 Gravity separation is the oldest known ore beneficiation technique and is practiced extensively in ‘Nature’ Earliest recorded human use of gravity separation was recovery of gold by panning from the Upper Nile by ancient Egyptians, dating back to 1900 BCE Gravity separation is a physical process which consists of the separation of Gravity separation and Ore Beneficiation – IspatGuruGravity Separation Of Iron Ores gravity ore dressing gravity beneficiation gravity separation is one of the main ore beneficiation methods, includes heavy medium separation dms hms, jigging, shaker concentrator, spiral chute concentratorms and mineral jigs suit for the coarse ore particle, shaker has a high dressing accuracy, can be used in the weak magnetic Gravity Separation Method For Iron Ore

Separation process of iron ore,iron ore magnetic separation

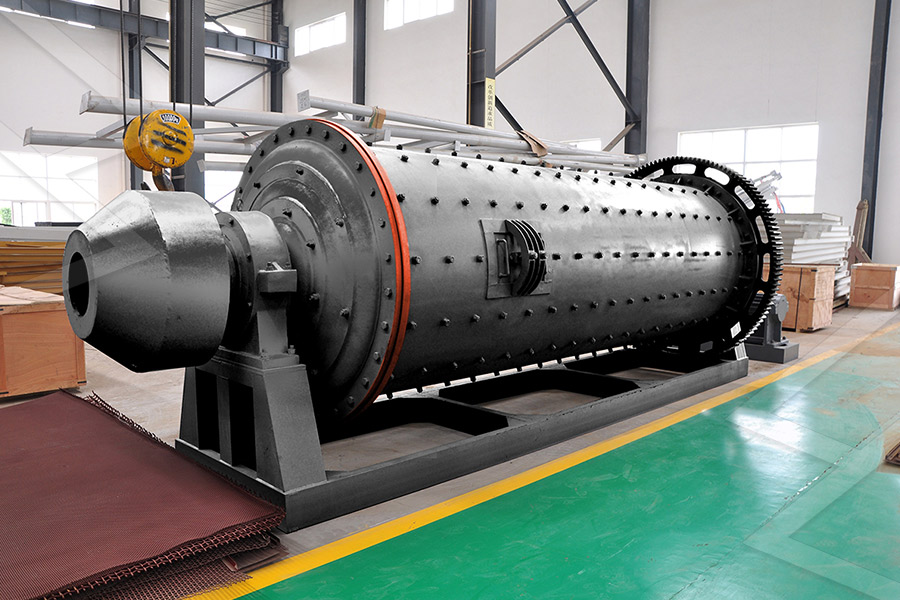

08092020 Gravity separation process and strong magnetic separation process are mainly used to separate coarsegrained (2mm20mm) and mediumgrained weakly magnetic iron ore Among them, coarse and extremely coarse (greater than 20mm) ores are commonly used in heavy medium or jigging gravity separation technology; Mediumgrained iron ore adopts flow Gravity separation of ultrafine iron ore in the REFLUX Feb 26, 2021 The REFLUX™ Classifier is a recently developed waterbased gravity separation technology that is already being used worldwide to beneficiate particles above 0100 mm in size This paper reports tests performed on an ultrafine iron ore with nominal top size of 0106 mm, but with 59 wt% being gravity seperation of ironGravity Seperation Iron Ore Gravity Seperation Iron Ore Iron ore beneficiation university of newcastleFine gravity separation reflux classifierThe primary purpose of this project is to use the reflux classifier to process iron ore feeds in the 10 0045 mm size range to produce a highquality freedraining iron ore product that is Gravity Separation Process Iron

Gravity Seperation Of Iron Ore

Magneticgravity Separation Of Iron Ore Magneticgravity separation of iron ore P A Usachyov S Yu Korytny Mining Institute, Kola Science Centre, Russian Academy of Sciences, 24 Fersman str, Apatity, Munnansk region, Russia Received 17 October 1997 accepted 30 April 199S In order to produce highgrade ironore concentrates a magnetic The main mechanicalphysical methods for PCB recovery include magnetic separation [15,16], gravity separation [17,18], electrostatic separation [19,20], and vacuum metallurgy [21,22]The highgradient magnetic separator has been applied to the separation of paramagnetic iron elements from metal concentrates [23,24], which could obtain the magnetic (MA) and non Gravity Seperation Of IronHeavy Media Gravity Separation Heavy media gravity separation involves using a mixture of fine media material such as magnetite (SG 51) or ferrosilicon (SG 68 Service Online "Physicochemical processing of low grade This study is focused on the develop of a cost effective physicochemical beneficiation process for low grade ferruginous gravity separation of iron ores monteurzimmerunterkunftde

Gravity separation Wikipedia

Gravity separation is an industrial method of separating two components, either a suspension, or dry granular mixture where separating the components with gravity is sufficiently practical: ie the components of the mixture have different specific weight All of the gravitational methods are common in the sense that they all use gravity as the dominant forceGravity Concentration of Iron Ore CORE Gravity Concentration of Iron Ore By R K Rath and Ratnakar Singh Get PDF (4 MB) Abstract Gravity concentration process is the oldest beneficiation method known to mankind This is a physical process and exploits the differences in densities of minerals to bring about a separationgravity separation of iron ore pdf5 Application of gravity separator Gravity separator is suitable for the treatment of ore or other materials with a large density difference between useful minerals and gangue It is an effective method for treating ore, medium and fine (substantially bound to be larger than 25 mm, 252 mm, 201 mm) ore In the treatment of fine slime (less Gravity Separator Machine for Sale JXSC Mining