limestone grinding plant process

2020-02-02T11:02:05+00:00

Daswell Limestone Grinding Plant Solutions for Calcium

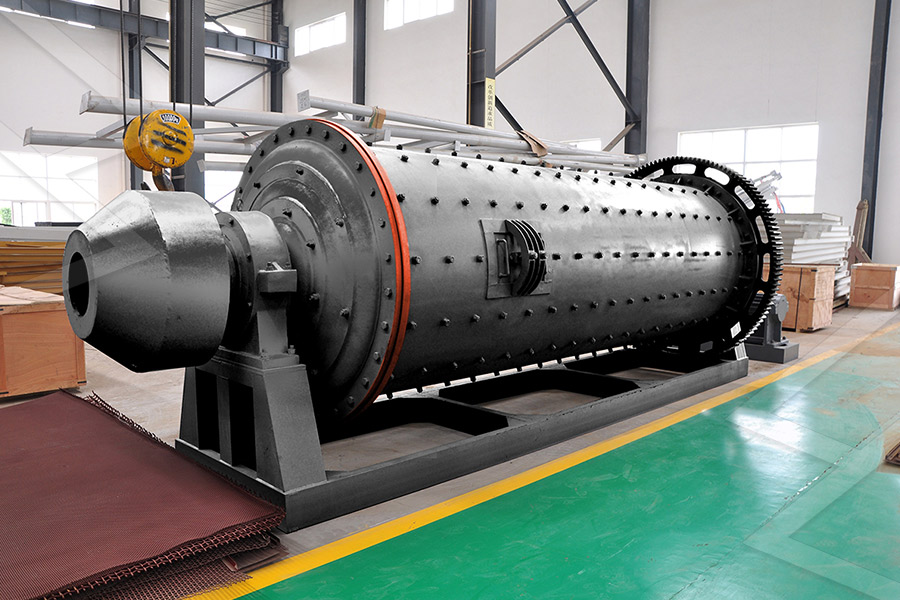

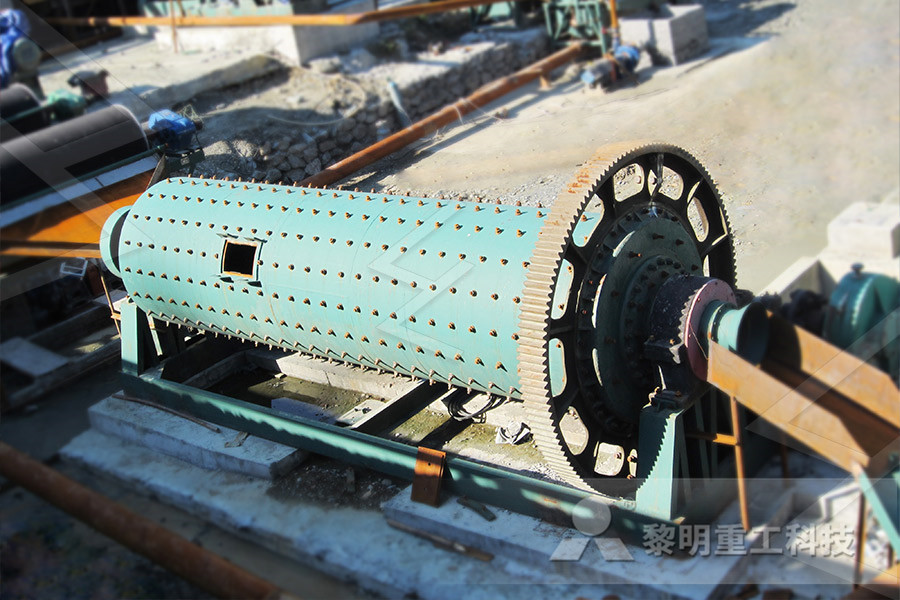

Daswell Limestone Powder Grinding Plant Daswell machinery is a professional manufacturer and supplier of mineral processing plants, such as calcium carbonate plant, lime calcination plant, lime hydration plant, ground silica making plant and others With development of world economy, these industrial minerals are in great demand The limestone grinding process consists of three steps: crushing, grinding and bagging First, crush the limestone in the main crusher Next, grind in the Raymond powder mill Last, qualified limestone can be bagging and be put in production storage, but others have to be ground again The can be made depend on the requirement of fineness of Limestone Grinding Plant Grinding Equipment SupplierLimestone Grinding Plant Limestone Mill Limestone Crusher Jul 10, 2020 The process of the limestone grinding plant is that the limestone of large size is coarsebroken and mediumbroken, and then it enters into the grinding mill for powder making and grinding, and then carries out the wind separation and classification, and finally collects the finegrained finished products to Limestone Grinding Plant Process

limestone grinding plant

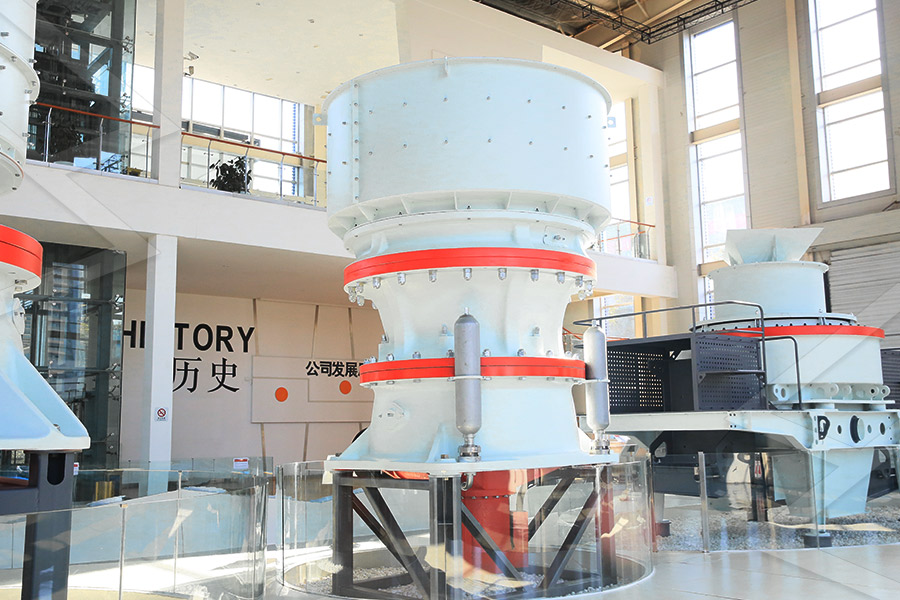

Limestone is the main raw material for the manufacture of cement, lime and calcium carbide, and is an indispensable flux limestone in the metallurgical industry After ultrafine grinding, highquality limestone is widely used in the manufacture of power plant desulfurizers, concrete admixtures, paper, rubber and other productsBesides, micro powder grinding mill can process minerals smaller than 10mm and Mohs’s harness below 5 And Raymond mill can process minerals of 2035mm, and produce powder of 23198μm Last but not least, vertical mill can grind minerals whose size is below 40mm and produce powder of 85100μm limestone bariteLimestone Processing Plants Of Various Types With Low Daswell offers tailored turnkey solutions for limestone processing plants, including designing and planning plants and supplying relevant equipment Daswell limestone processing plants, be the limestone grinding plant, limestone calcining plant or lime hydration plant, are designed and delivered according to customers’ needs, such as Turnkey Solutions for Limestone Processing Plant

Limestone Processing Plant, Limestone Grinding Machine

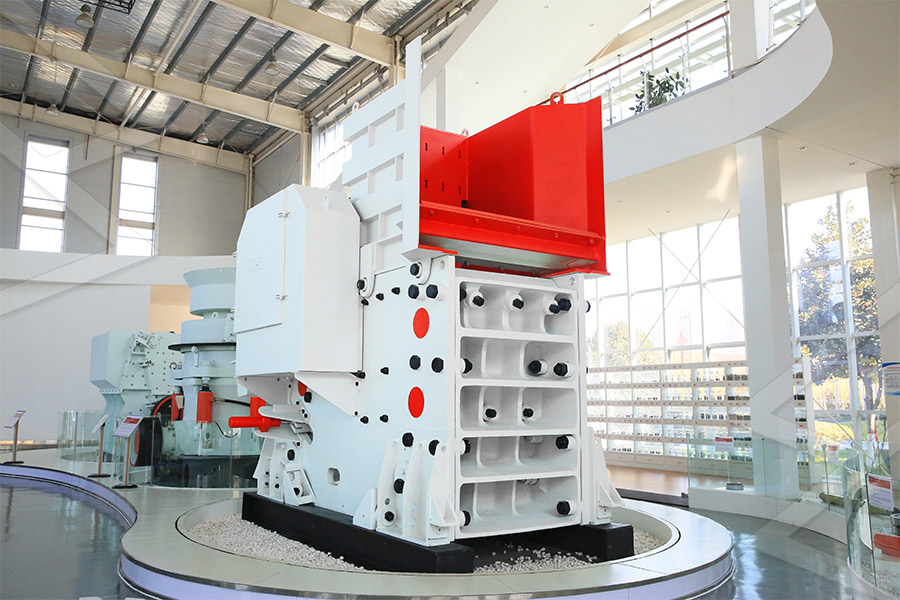

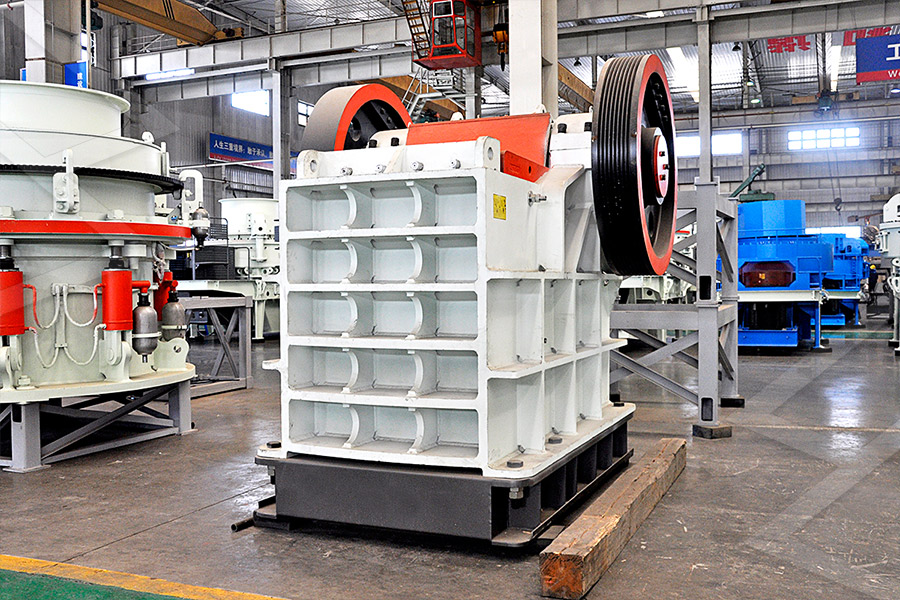

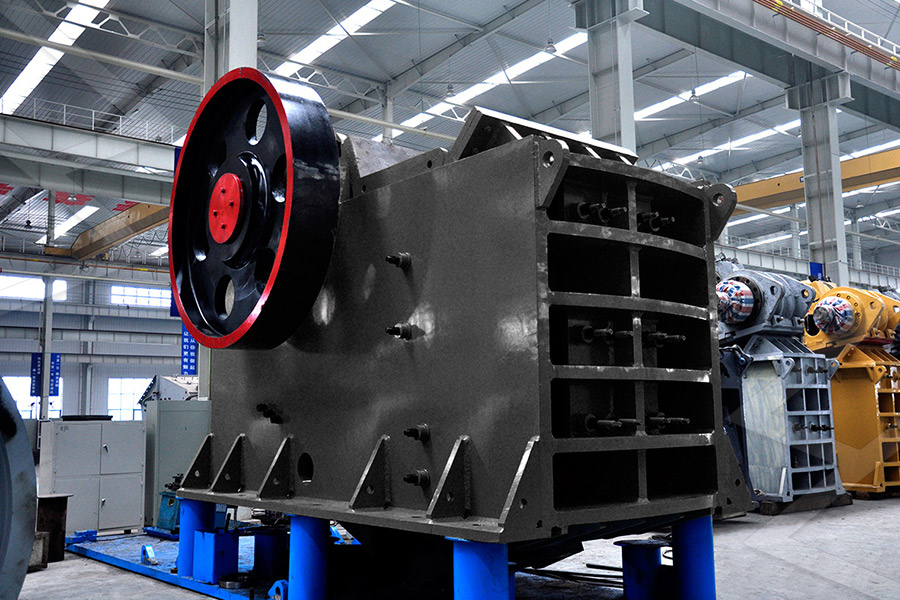

Production Process First stage: limestone chunks are transported by special vehicles to raw materials bin, after the forklift / artificial then delivered to the jaw crusher for crushing by forklift or man Second stage: Crushed limestone is lifted to the hopper by hoist, then transported by feeder Third stage: Qualified products after the grinding process enter the collector through The purpose of Limestone Powder grinding plant is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar Limestone Powder Grinding Plant The limestone grinding mill belongs to the vertical grinding mill with small footprint Limestone mill can form the independent grinding production system, thus it can efficiently and safely do the lime production process for a long time In addition, if the customers have the higher fineness requirement on the limestone powder, they can choose Configuration and Process Flow of Limestone Milling Plant

EFFICIENT PROCESSES Wet limestone grinding for FGD

wet grinding References Equipment for the efficient FGD circuit Especially in power plant operations the highest demands prevail on operational safety, redundancies and reliable processes Christian Pfeiffer supplies engineering, mills and auxiliary equipment for limestone wet grinding plants in open and closed circuits which are optimally suit Limestone is the main raw material for the manufacture of cement, lime and calcium carbide, and is an indispensable flux limestone in the metallurgical industry After ultrafine grinding, highquality limestone is widely used in the manufacture of power plant desulfurizers, concrete admixtures, paper, rubber and other productslimestone grinding plantLimestone Grinding Plant Limestone Mill Limestone Crusher Jul 10, 2020 The process of the limestone grinding plant is that the limestone of large size is coarsebroken and mediumbroken, and then it enters into the grinding mill for powder making and grinding, and then carries out the wind separation and classification, and finally collects the finegrained finished products to Limestone Grinding Plant Process

Limestone Processing Plant, Limestone Grinding Machine

Production Process First stage: limestone chunks are transported by special vehicles to raw materials bin, after the forklift / artificial then delivered to the jaw crusher for crushing by forklift or man Second stage: Crushed limestone is lifted to the hopper by hoist, then transported by feeder Third stage: Qualified products after the grinding process enter the collector through The purpose of Limestone Powder grinding plant is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble, talcum, barite, gypsum, dolomite, bentonite mud, mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar Limestone Powder Grinding Plant The limestone grinding mill belongs to the vertical grinding mill with small footprint Limestone mill can form the independent grinding production system, thus it can efficiently and safely do the lime production process for a long time In addition, if the customers have the higher fineness requirement on the limestone powder, they can choose Configuration and Process Flow of Limestone Milling Plant

Limestone Grinding Plant, Limestone Mill, Limestone Crusher

The process of the limestone grinding plant is that the limestone of large size is coarsebroken and mediumbroken, and then it enters into the grinding mill for powder making and grinding, and then carries out the wind separation and classification, and finally collects the finegrained finished products to complete the grinding process Limestone Grinding Plant in Manila, Philippines This site is located in Manila, Philippines This grinding line consists of four sets of MTW215 Grinding Plant, and it won’t process limestone until the size is smaller than 01mm The final products are used in power plant desulfurization MTW215 European type Grinding Plant is famous for Limestone Grinding Plant LIMING(Shanghai) Guizhou 80,000TPY Limestone Grinding Plant Customer Address: Guizhou, China Input Material: Limestone Finished Particle Size: 180mesh, 250mesh Barite powder grinding process; CASE India 35TPH Limestone Grinding Plant; Bangladesh 4TPH Feldspar Quartz Grinding Plant Limestone Processing Plant Grinding Mill

Processing plant of limestone ultra fine powder grinding

Limestone ultra fine powder grinding mill is the main equipment in the process of limestone, the past of limestone powder grinding mill for processing the fineness, generally less than 300 mesh,it cant meet the needs of the limestone powder industry, aim at this situation, Shanghai Clirik machine co, LTD, the engineering and technical personnel after years of Part 1: coarse crushing step The limestone raw material would sent to the limestone jaw crusher by the vibrating feeder for crushing And the larger material will crush into the feed size of the next process The crushed stone will transport to the transfer bin by the conveyor belt Part 2: Limestone Crushing Plant Limestone Crusher Limestone Limestone is the main raw material for the manufacture of cement, lime and calcium carbide, and is an indispensable flux limestone in the metallurgical industry After ultrafine grinding, highquality limestone is widely used in the manufacture of power plant desulfurizers, concrete admixtures, paper, rubber and other productslimestone grinding plant

Limestone Grinding Plant Process

Limestone Grinding Plant Limestone Mill Limestone Crusher Jul 10, 2020 The process of the limestone grinding plant is that the limestone of large size is coarsebroken and mediumbroken, and then it enters into the grinding mill for powder making and grinding, and then carries out the wind separation and classification, and finally collects the finegrained finished products to Production Process First stage: limestone chunks are transported by special vehicles to raw materials bin, after the forklift / artificial then delivered to the jaw crusher for crushing by forklift or man Second stage: Crushed limestone is lifted to the hopper by hoist, then transported by feeder Third stage: Qualified products after the grinding process enter the collector through Limestone Processing Plant, Limestone Grinding Machine The process of the limestone grinding plant is that the limestone of large size is coarsebroken and mediumbroken, and then it enters into the grinding mill for powder making and grinding, and then carries out the wind separation and classification, and finally collects the finegrained finished products to complete the grinding process Limestone Grinding Plant, Limestone Mill, Limestone Crusher

Limestone Processing Plant Grinding Mill

Guizhou 80,000TPY Limestone Grinding Plant Customer Address: Guizhou, China Input Material: Limestone Finished Particle Size: 180mesh, 250mesh Barite powder grinding process; CASE India 35TPH Limestone Grinding Plant; Bangladesh 4TPH Feldspar Quartz Grinding Plant The model selection scheme of limestone powder making main engine Product specification (mesh) 95%particles’ grain size is over 200meshes 90% particles’ grain size is over 250meshes 90% particles’ grain size is over 325meshes, model selection scheme Vertical mill or large scale Raymond mill 1.Power consumption: 18~25kWh/ton, it Limestone Mill High Efficiency, Large Capacity, 2002500 Limestone makes up about 10% of the total volume of all sedimentary rocks Limestone has been used as a building material, as aggregate for the base of roads, as white pigment or filler in products such as toothpaste or paints, and as a chemical feedstock As used limestone processing plant usually produce products with better shapesUsed Limestone Processing Plant Grinder Process

Limestone processing equipment Schenck Process

We make processes work Schenck Process your partner worldwide With an unrivaled global network of operating companies and competent partners, the name Schenck Process is synonymous throughout the world with process expertise and wellengineered measuring technology for weighing, feeding, conveying, screening, automation and air filtrationwet grinding References Equipment for the efficient FGD circuit Especially in power plant operations the highest demands prevail on operational safety, redundancies and reliable processes Christian Pfeiffer supplies engineering, mills and auxiliary equipment for limestone wet grinding plants in open and closed circuits which are optimally suitEFFICIENT PROCESSES Wet limestone grinding for FGDGrinding on the ready2grind system The ready2grind system is extraordinarily compact The modules in standard container sizes are delivered preassembled The grinding process is the same as that of bigger Pfeiffer grinding plants The above flow sheet shows the process of cement grinding as an example Clinker and additives are ground, dried Modular grinding plant Mill system ready2grind Gebr