Effect Of Ball Size On The Critical Speed Of Ball Broyeur À

2023-09-04T09:09:08+00:00

Effect Of Ball Size On The Critical Speed Of Ball Mill

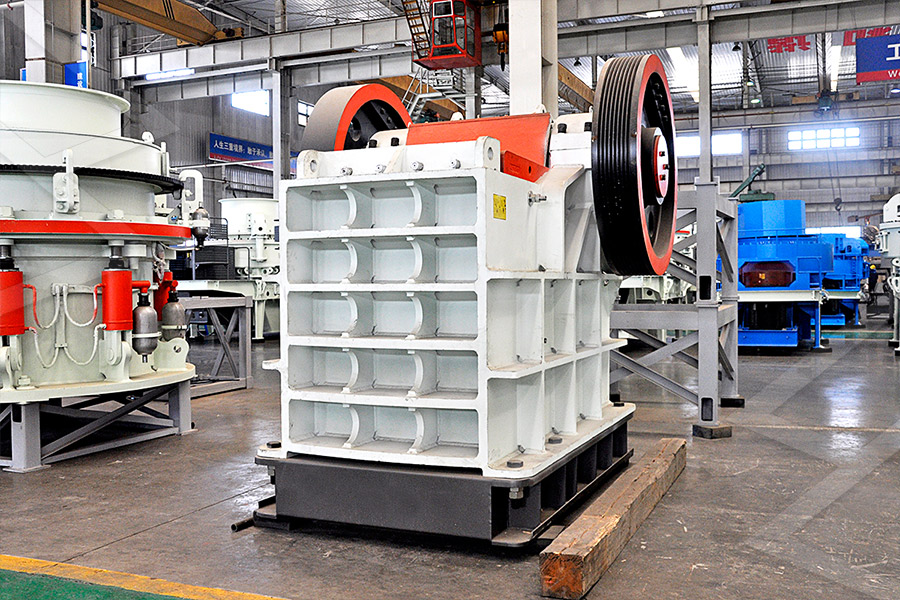

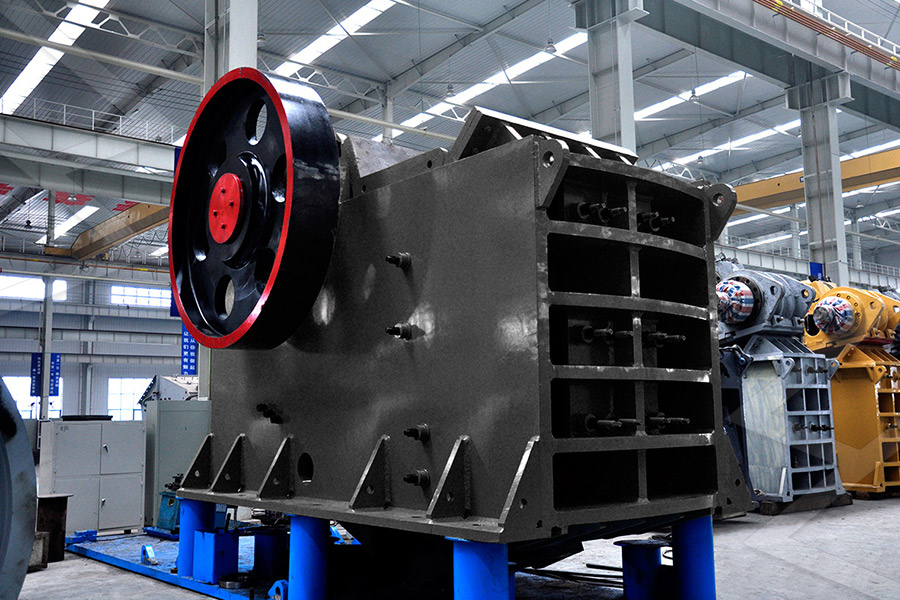

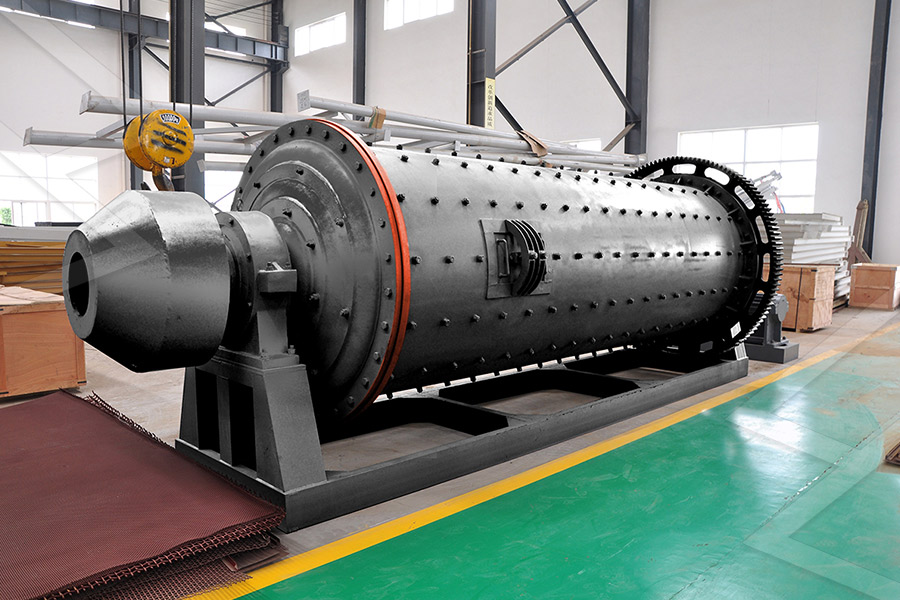

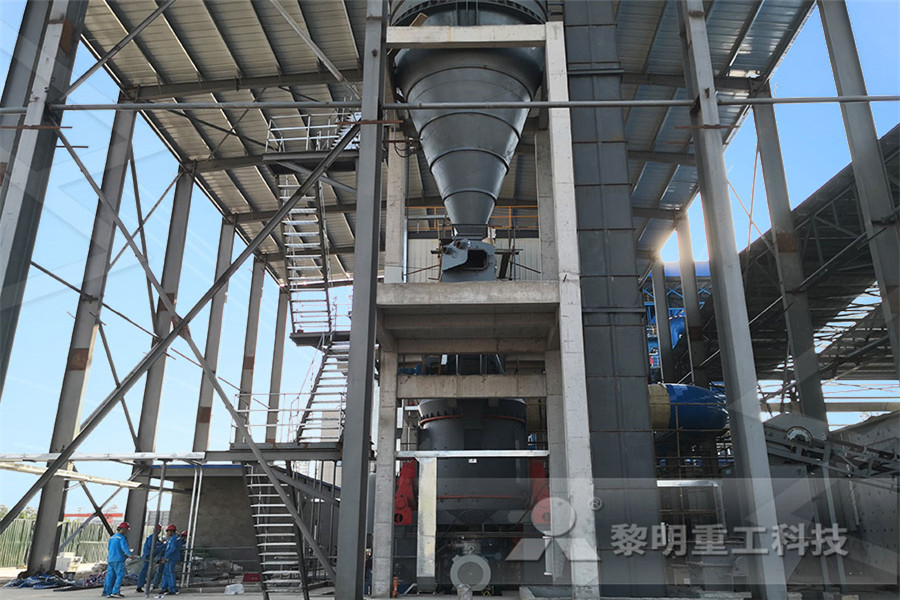

The experimental mill used was a laboratory scale ball mill of 150 mm dia170 mm lengthgiving a total volume of 3000 cc, with steel balls of 25mm dia, so as to occupy 50 of the ball mill volume and an operating speed of 60 rpm, which is 70 of the critical speed of the ball mill The feed Cement Mill Notebook Free size and type of liners 31 Critical Speed: at 7476% 32 Calculation of the Critical Mill Speed: G: weight of a grinding ball Mechanical milling of aluminum powder usingeffect of ball size on the critical speed of ball mill01/05/1976 The specific rates of breakage of particles in a tumbling ball mill are described by the equation S i = ax α i (Q(z), where Q(z) is the probability function which ranges from 1 to 0 as particle size increasesThis equation produces a maximum in S, and the particle size of the The effect of ball size on mill performance ScienceDirect

Effect of Ball Weight on Speed, Accuracy, and Mechanics

The aims of this study were: (1) to quantify the acute effects of ball weight on ball release speed, accuracy, and mechanics in cricket fast bowling; and (2) to test whether a period of The experimental mill used was a laboratory scale ball mill of 150 mm dia170 mm lengthgiving a total volume of 3000 cc, with steel balls of 25mm dia, so as to occupy 50 of the ball mill volume and an operating speed of 60 rpm, which is 70 of the critical speed of the ball mill The feed size of the material used was of aEffect Of Ball Size On The Critical Speed Of Ball MillJul 01, 2020 The effect of ball size distribution increased with increasing mill filling and for the mill filling of 35%, the ball size distribution had the maximum effect on the power draw Ball Mill Critical Speed Mineral Processing Metallurgy Jun 19, 2015 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at effect of ball size on the critical speed of

effect of ball size on the critical speed of ball mill

These speeds are 290%, 579%, and 869% of the critical speed given by the relation, N c =4229D −1/2, where N c is the critical rotation speed (in rpm) and D is the inner diameter of the ball container (in meterThe Effects Of Ball Size On The Determination Of In the experiments, 75 of the rotational speed of the ball mill, the critical speed of the mill, \(nc\), is taken the ball mill characteristics and test conditions that are used are given below: the effect of ball size on mill performance, powder technol, 1976, vol 14, pp 71–79 12 read moreEffect Of Ball Size On The Critical Speed Of Ball Mill In01/12/2013 The effect of ball size on the particle size reduction has been investigated first for varying rotation speed of the container Percent passing and size distributions of the milled Al 2 O 3 powder are shown in Fig 1, Fig 2, respectively, as a function of particle size for varying ball sizeThe average particle sizes (d 50) of the milled Al 2 O 3 powder are shown in Fig 3 as a Effect of ball size and powder loading on the milling efficiency

Effect Of Ball Size On The Critical Speed Of Ball Mill Htm

The effect of ball size on mill performance ScienceDirect 01/05/1976 The specific rates of breakage of particles in a tumbling ball mill are described by the equation S i = ax α i (Q(z), where Q(z) is the probability function which ranges from 1 to 0 as particle size increasesThis equation produces a maximum in S, and the particle size of the maximum is related to ball diameter by The Effect of the Lifter Face Angle and Ball Size 8 Mill Diameter 36 Lifter Height 10 % Critical Speed 76% Ball Size 5 Mill Diameter 36 Lifter Height 10 % Critical Speed 76% Ball Mill An Overview Sciencedirect Topics Generally, a maximum allowed ball size is situated in the range from D /18 to D/24 The degree of filling the mill with balls Effect Of Ball Size On The Critical Speed Of Ball Milleffect of ball size on the critical speed of ball mill effect of ball size on the critical speed of ball mill Size Reduction and Mill SpeedCritical as cataracting will generate high impact but also greatly increase mill wear Read More The Effect of Ball Size Diameter on Milling Performance The critical grinding speed Vc of a ball mill in rpm is given by 20 as 342 Effect Of Critical Speed Increasing On Product Size Grinding Ball

The Effect of Ball Size Diameter on Milling Performance

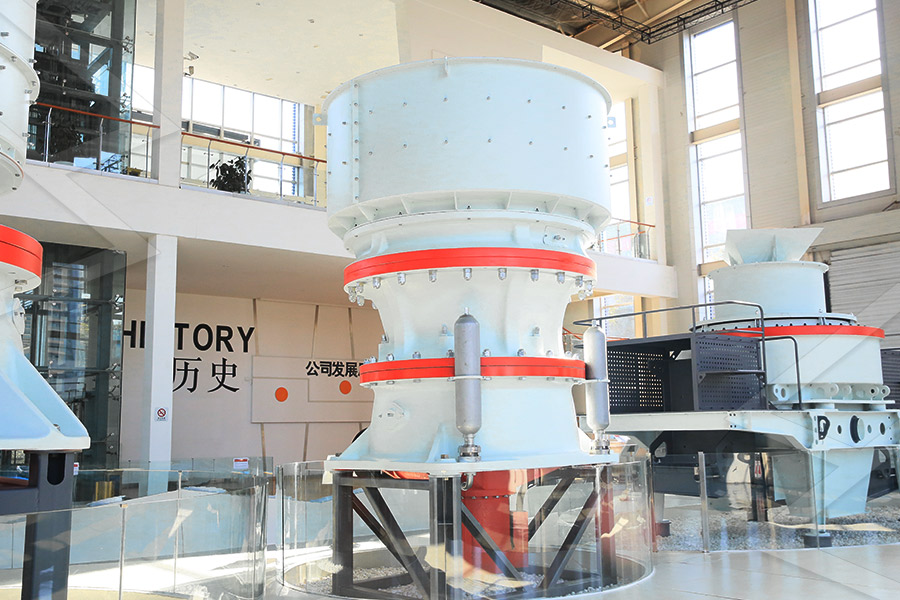

The critical speed is the speed at which the mill load sticks to the walls of the mill during rotation The aim of this project was to determine the effect of the ball diameter on the operating parameters of the mill, which included the energy efficiency, the power requirement, mill load, critical speed as well as the size reduction of the mill The critical speed of the mill, c, is defined as the speed at which a single ball will just remain against the wall for a full cycle At the top of the cycle =0 and Fc Fg (85) mp 2 cDm 2 mpg (86) c 2g Dm 1/2 (87) The critical speed is usually expressed in terms of the number of revolutions per second Nc c 2 1 2 2g Dm 1/2 (2 981)1/2Effect Of Critical Speed In Ball Milling On GrindEFFECT OF MEDIA SIZE IN STIRRED BALL at speeds above critical, and the grinding media size corrosion and size of balls, size of mill and mill speed Know More Ball Mill Ball Size Crusher Mills, Cone Crusher,effect of ball size on the critical speed of ball mill

effect of ball size on the critical speed of ball mill

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 micronsBall Mills Mine The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed Ball Mills are generally used to grind material 1/4 inch Jul 01, 2020 The effect of ball size distribution increased with increasing mill filling and for the mill filling of 35%, the ball size distribution had the maximum effect on the power draw Ball Mill Critical Speed Mineral Processing Metallurgy Jun 19, 2015 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at effect of ball size on the critical speed ofeffect of ball size on the critical speed of ball mill effect of ball size on the critical speed of ball mill Size Reduction and Mill SpeedCritical as cataracting will generate high impact but also greatly increase mill wear Read More The Effect of Ball Size Diameter on Milling Performance The critical grinding speed Vc of a ball mill in rpm is given by 20 as 342 Effect Of Critical Speed Increasing On Product Size Grinding Ball

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

522 Original equipment manufacturer recommended ball size distribution 64 53 Results and discussion 65 531 Ball size distribution effect 65 532 Validation of ball mixture model 67 533 Significance of findings 68 54 Summary 70 Chapter 6 Conclusion 71 61 Introduction 71 62 Summary of findings 71 621 Ball size effect 71The critical speed of the mill, c, is defined as the speed at which a single ball will just remain against the wall for a full cycle At the top of the cycle =0 and Fc Fg (85) mp 2 cDm 2 mpg (86) c 2g Dm 1/2 (87) The critical speed is usually expressed in terms of the number of revolutions per second Nc c 2 1 2 2g Dm 1/2 (2 981)1/2Effect Of Critical Speed In Ball Milling On Grind06/08/2015 Effect of Speed and Filling on Power In this section, a 0545m x 0304m ball mill is simulated to study the combined effect of mill speed and filling on the power draft of the mill Mill operating speed and filling, among other things, are known to affect the power draft Mill performance is at its best when these two operating parameters Tumbling Mill Critical Speed Mineral Processing Metallurgy

Predicting the effect of operating and design variables

01/04/2013 Typical results from simulations of batch grinding of limestone #1 (30% ball load, 25 mm ball size and 68% of critical speed in a 03 m The effect of ball size on specific breakage rates predicted using the mechanistic model is illustrated in Fig 14 for selected materials, and shows that the model is capable of accounting for the shift in the size corresponding to the 11/11/2019 The critical speed of a ball screw is the first order natural frequency of the screw shaft As a screw shaft rotates, it begins to whip – much like a jump rope This behavior limits the screw’s critical speed A screw shaft will naturally experience some bending, or sagging, due to its own weight As the screw rotates, it tends to vibrate Difference between ball screw critical speed and characteristic speedThe effect of ball size on copper powder particle morphology in drytype milling was studied using a planetary ball mill Spherical copper powders were obtained by (PDF) USING DISCRETE ELEMENT METHOD TO INVESTIGATE BALL